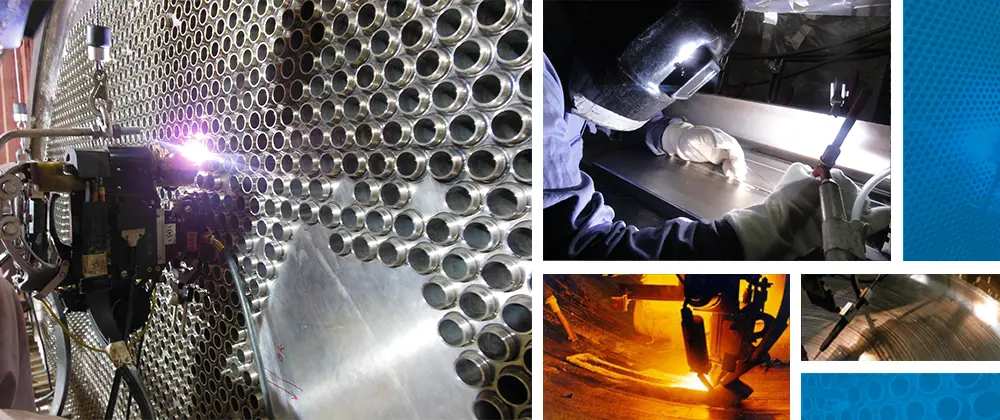

Comprehensive Welding Capabilities

Ìý

Continuous improvement in Welding Technology has enabled the development of over 6000 welding procedures qualified as per international codes and standards - ASME, BS, EN/ISO, AS/NZ - for a variety of materials in a range of thickness (0.5 to 800 mm) covering the complete spectrum of welding processes. Specialised fabrication facilities include 100,000 class dust-free enclosures with areas of 1000 sq. m. and 400 sq. m.

| Welding Processes | SMAWÌý | ÌýGTAW | GMAWÌý | FCAWÌý |

| SAW | PAWÌý | ESWÌý | Arc Stud Welding | |

| CD Stud WeldingÌý | Electron Beam Welding Laser Beam Welding | Resistance Spot Welding | Ìý |

| WeldedÌýMaterials | Carbon steelsÌý | Austenitic stainless steels | Low alloy steels including Cr-Mo-VÌý | Quenched & tempered steelÌý |

| Duplex, super duplex & hyper duplex stainless steel | Nickel based alloys (Inconel, Incoloy, Hastelloy, Monel)Ìý | Copper based alloys (Cupro-Nickel, aluminium bronze, brass) | Titanium & Titanium alloys | |

| Aluminium & Aluminium alloysÌý | Maraging Steel | Clad steels with stainless steel, Inconel, monel, cupro-nickel, titanium etc. | Ìý |

| Specialised Welding Techniques | Tandem/ Twin SAWÌý | Semi-Automatic GTAW/SAW | Robotic | Hot Wire GTAWÌý |

| Activated - TIG | Narrow/ Ultra-Narrow Gap SAW/GTAW | Pulsed GTAW/GMAW | Internal BoreTube to Tubesheet | |

| Cold Metal Transfer (CMT) | Self-Shielded FCAW | Orbital GTAW | ÌýStrip Cladding | |

| High Speed ESWÌý | ||||

Ìý